Tianjin Huichi Metal Materials Co. LTD

Name:Mary

Cell:86-15122997517

Whatsapp:86-15122997517

Email:[email protected]

Name:Aileen

Cell:86-18822070408

Whatsapp:86-18822070408

Email:[email protected]

| Material Grade | Pure Nickel,Hastelloy series,Monel series,Incoloy series,Inconel series,Nitronic series,Alloy series, |

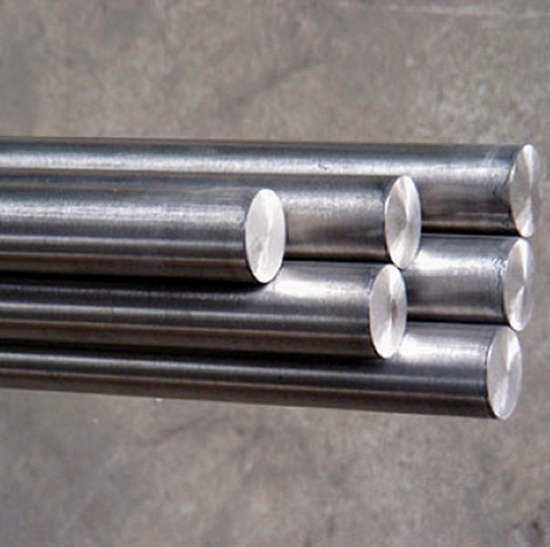

| Size | 8-800mm |

| Shape | round,square,hexagonal |

| Process | hot rolled, forged, cold drawn |

| Finish | black,bright |

| Status | solution pickling; heat treatment |

8. GH series:GH4169, GH4145, GH4105, GH4049, GH4033, GH4043,4180, GH3030, GH3536, GH3128, GH2132, GH1131,etc

Hastelloy C276 Alloy Description

Corrosion resistance The Hastelloy C-276 alloy belongs to the nickel-molybdenum-chromium-iron-tungsten nickel base alloy. It is the most resistant to modern metal materials. Main moisture-resistant chlorine, a variety of oxidizing chloride, chloride solution, sulfuric acid and oxidizing salt, in the low temperature and medium temperature hydrochloric acid have good corrosion resistance. Therefore, nearly three decades, in the harsh corrosive environment, such as chemical, petrochemical, flue gas desulfurization, pulp and paper, environmental protection and other industrial areas have a very wide range of applications.

Hastelloy C-276 alloy of various corrosion data is typical, but can not be used as a norm, especially in the unknown environment, must be tested before they can be selected. Hastelloy C-276 alloy does not have enough Cr to withstand the strong oxidizing environment corrosion, such as hot concentrated nitric acid. The production of this alloy is mainly for the chemical process environment, especially in the case of mixed acid, such as flue gas desulfurization system, such as the discharge tube. The following table shows the corrosion test of the four alloys in different environments.

Scan the QR code